Case Study: Inventory Management During Product Rundown

All items have a lifecycle which starts with product evaluation and evolves through to end-of-life. While there is typically a large focus on financial performance at the launch of a product, managing end-of-life rundown is equally as important. In each stage of a product’s lifecycle, the goal is to maximize sales, sell through, and return on investment (ROI). Despite the spotlight on new product launches, rundown planning is a critical step in reducing returned items and establishing trust with the retailer. Poor maintenance of obsolete inventory can result in reduced shelf space for newer products or those in high demand. With precise management of DC-store-item level data, it is possible to create an accurate order forecast that empowers CPGs to get near-zero inventory numbers on targeted exit dates.

Managing Product-Level Inventory to Maximize Sales

A Fortune Top 25 consumer packaged goods (CPG) company approached RSi with a need to estimate waste cost related to the rundown of a personal care brand. However, once they were introduced to the RSi’s store-item-day data granularity, they realized RSi could offer much more. By monitoring the inventory levels at both the store and distribution center (DC) level, they could also maximize profit during inventory rundown.

Driving Bottom-Line Growth with Real-Time Insights

As a first step, RSi ran a series of store-item level reports to discover which stores were carrying excess inventory of the CPG’s personal care brand. This allowed for the identification of specific stores that would likely struggle to sell through the products prior to the targeted exit date. Using this information, the CPG was able to work with their retailer to immediately shut down replenishment on the overstocked stores to minimize reclaim. Additionally, they used the analysis to proactively adjust inventory replenishment on other stores with high sales velocity.

Through deeper analysis, and by leveraging RSi’s Rundown Growth Driver report, the CPG was able to select and compare the thresholds and tolerances needed to determine the timing of when rundown-driven inventory depletion.

Significant Improvements in Rundown Management and In-Store Accuracy

In the end, by leveraging RSi’s deep granular data analytics and reporting solutions, more effective rundown management generated $500k in incremental sales for the CPG. The company also exceeded their initial waste cost estimate by over 60% and achieved 30% true cost avoidance.

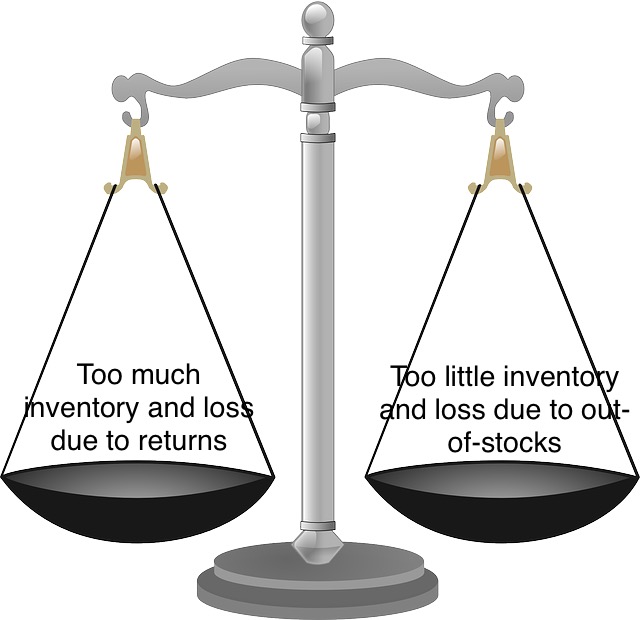

Scales of Profitability

RSi has a wide range of solutions to help you understand, track and optimize your rundown management. Our Essential Growth Drivers help to arm CPG manufacturers with the tools they need to maximize product performance throughout every stage of the product lifecycle, increasing overall sales and profitability. If you need to expand your analytical resources and accelerate your results, you can also tap into RSi’s expert resources on-demand with Professional Services. RSi Data Scientists will create, automate and optimize the performance of your mission-critical reports, dashboards and analytical tools with custom report creation. Learn more about how to get free custom report creation here.

Leave a Reply

You must be logged in to post a comment.